-

Output

Up to 450 bags/hour

-

Product type

Powdered and low granularity

-

Type of bag

Paper valve bags

-

Automation level

Automatic

Benefits

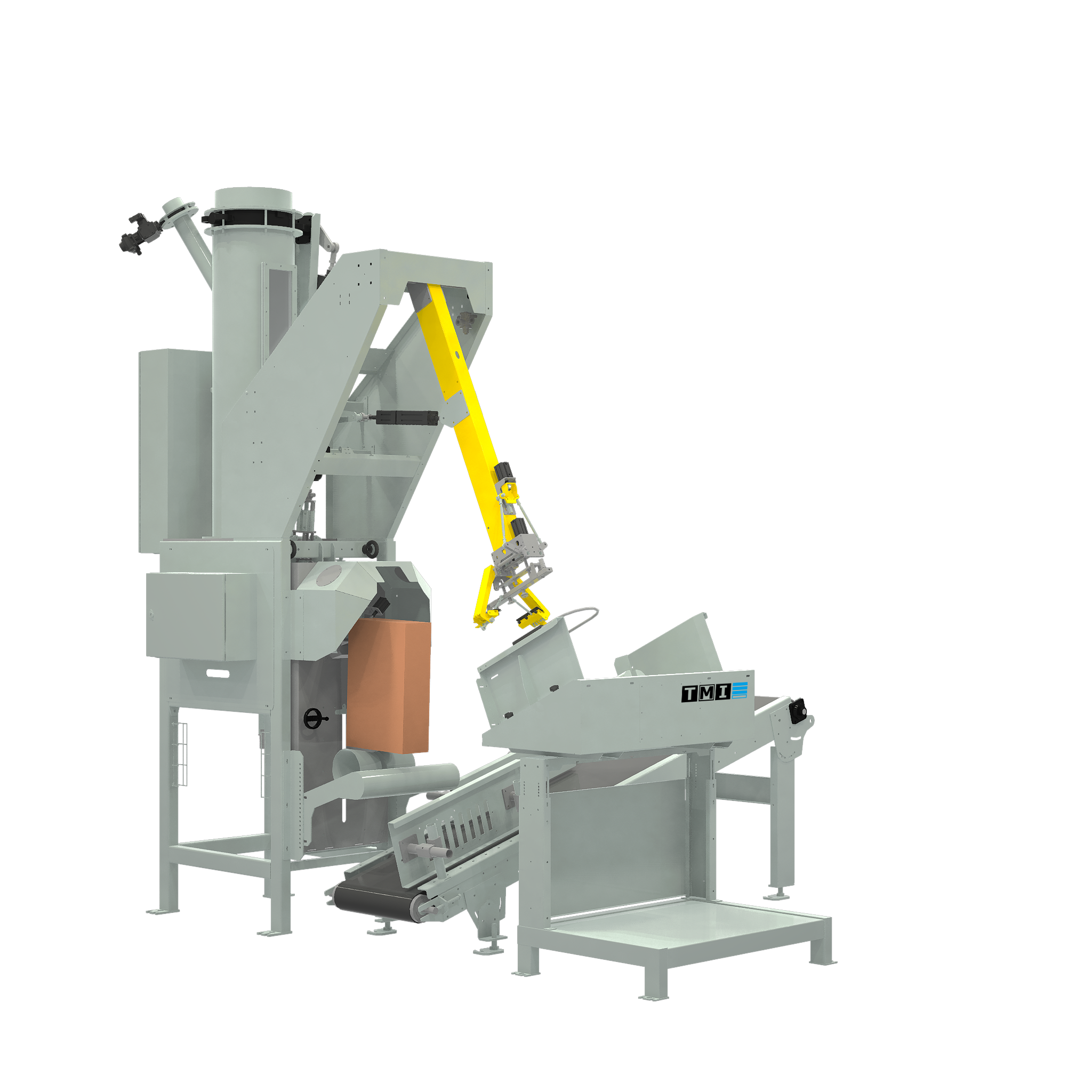

THE AUTOMATIC VALVE BAGGING MACHINE ILERSAC VBF PROVIDES...

- Total automation of the valve bag filling process: the automatic bag feeding arm together with the recipe configuration allow the bagging process to be performed automatically, from the moment the empty bag is picked up and placed in the bagging spout to the evacuation of the full bag.

- Production flexibility: the automatic bagger enables optimum filling of valve bags with different products and bag formats.

- Optimized bagging of powdery products: using the force of air, the fluidization dosing system pushes the product into the valve bag in a sustained flow, until the bag is completely filled.

- Mixes that are always heterogeneous: thanks to its multi-fluidization options, this valve bagging machine avoids the segregation of heterogeneous products, maintaining the distribution of the different components of the product also inside the bag.

- Dust-free working environment: despite not being usual on valve bagging machines, ILERSAC VBF manages to bag powdery products keeping dust generation to a minimum, thanks to its multiple configuration options at the bagging point, always according to the requirements of each project.

- Durability: ILERSAC VBF is often used to handle abrasive products. This is why it has special configurations that significantly delay the wear and tear of its components.

- Minimum maintenance: this automatic bagging machine configuration does not include mechanical product drive elements, thus reducing routine maintenance.

- Easy cleaning: Corner-free sections with no mechanical elements can be quickly cleaned when changing products.

Download brochure

Download the catalogue to find out more about our solutions.